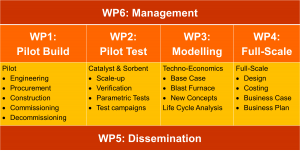

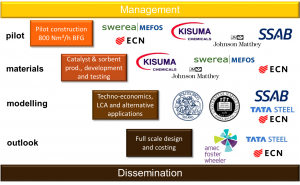

The STEPWISE project consists of the following workpackages.

WP-1: Design & Construction STEPWISE pilot unit

The objective is the design, construction and commissioning of a single column STEPWISE pilot installation. The pilot consists of 3 sections:

- a BFG compression unit

- an advanced pre-shift reaction section

- a single columns SEWGS section

The BFG compressor will deliver 800 Nm3/h BFG at 25 bar. The advanced pre-shift reaction section consists of 2 catalytic reactors in split-flow configuration, aiming at minimizing the steam requirement for the WGS reaction. The SEWGS section contains a single adsorption vessel of 60 cm diameter and a length of 9 meters, operated in pressure swing mode. It will effectuate the WGS reaction to completion and enable the H2/CO2 separation. Partners with proven capability in pilot plant design and construction will work closely in this WP, with input from the industrial partners. A site has been provided for the pilot in the slip stream of a real industrial BFG source.

WP-2:Testing and Development of STEPWISE pilot unit and materials

The required WGS catalyst and CO2 adsorbent will be tuned to operate with BFG and then produced at industrial scale. For the pre-shift section, initially a commercial Fe/Cr-based catalyst will be tested in the novel split-flow configuration, paying special attention to the sulphur present in the BFG. An advanced catalyst, tuned for low steam operation will be tested and compared. For the SEWGS section, the hydrotalcite-based adsorbent material will be produced at tonnage scale. Two test campaigns in the pilot unit, focusing on long duration behavior, will provide valuable feedback for reactor model optimization, the techno-economic assessment and the life cycle analysis.

WP-3: SEWGS modelling and integration in blast furnace plant

The testing program in WP-2 leads to optimized models for the WGS and SEWGS section. With the SEWGS model, cycle optimization will be performed to define the optimal sizing and configuration of the STEPWISE reactor vessels, to reduce the capture costs and to minimize the steam use while attaining the CO2 purity and CO2 avoidance target. The optimized cycle, in its turn, is incoroporated into the techno-economic process integration studies to allow comparison with other CO2 removal solutions. It will identify the optimum layout to minimize the energy efficiency penalties related to CO2 capture while maximizing economic benefits. Another important facet of WP3 will be the Life Cycle Analysis (LCA), which will compare the environmental footprints of the STEPWISE configuration to other CCS solutions that are applicable in the iron and steel industry (e.g. gas-liquid absorption).

WP-4: Process Basic Design and cost estimation full scale SEWGS unit for BF gas decarbonisation

The aim is to make a basic design and an accurate costs estimate for full scale SEWGS plant for CO2 capture from BFG. The optimized plant configuration from WP-4 together with the results of long term testing in WP-2, the sorbent optimization and costs of WP-3 will form the basis for this work. This work package will develop a comprehensive exploitation plan for the commercialization of the outcomes and developments within the project. Key will be the development of a business cases, including a public engagement strategy for implementing this technology, as part of the overall communication strategy.

WP-5: Dissemination

The project takes dissemination very seriously, and will aim activities at multiple levels, e.g. scientific community, public audiences and industrial community. At each level, there are several target audiences that have been identified. Activities will include website maintenance, press releases, meetings workshops, outreach to industrial platforms, scientific papers, national and international conferences and patents.

WP-6: Management

The project will be managed by the Project Coordinator as head of the Project Steering Committee, with representatives from each of the work packages and the participating organisations. Beside Project Management, Risk management forms an integral part of the whole project and is channelled through the Risk Manager.